In an effort to maintain the freshness and flavor of coffee beans, a variety of packaging techniques have been developed, including inert gas infusion, vacuum sealing, and direct insertion into drying machines. Among these methods, the prevailing and most effective solution in the market is the utilization of one-way valve coffee bean bags.

One-way valve coffee bean bags stand as a sophisticated solution meticulously designed to slow down the natural deterioration of coffee beans, especially during prolonged storage or transportation. They are recognized as one of the most reliable and commonly adopted methods in the industry.

Eight-side sealing is a pivotal feature in the construction of coffee bean bags, contributing significantly to the bag's structural integrity and overall effectiveness in preserving the quality of the enclosed coffee beans.

This technique involves the meticulous sealing of all eight sides of the bag, creating a secure and airtight enclosure. The process typically starts by folding and sealing each of the four corners of the bag, followed by sealing the edges along the sides. This results in a multi-dimensional, well-sealed structure that not only enhances the bag's strength but also prevents the entry of external elements.

The robustness achieved through eight-side sealing is particularly crucial in safeguarding the freshness of coffee beans. The sealed enclosure acts as a protective barrier, shielding the beans from environmental factors such as air, moisture, and light, all of which can contribute to the deterioration of the coffee's flavor and aroma.

Moreover, the eight-side sealing technique ensures that the bag maintains its shape and form, minimizing the risk of damage during handling, transportation, or storage. This is particularly important in scenarios where the bags might be stacked or subject to external pressure.

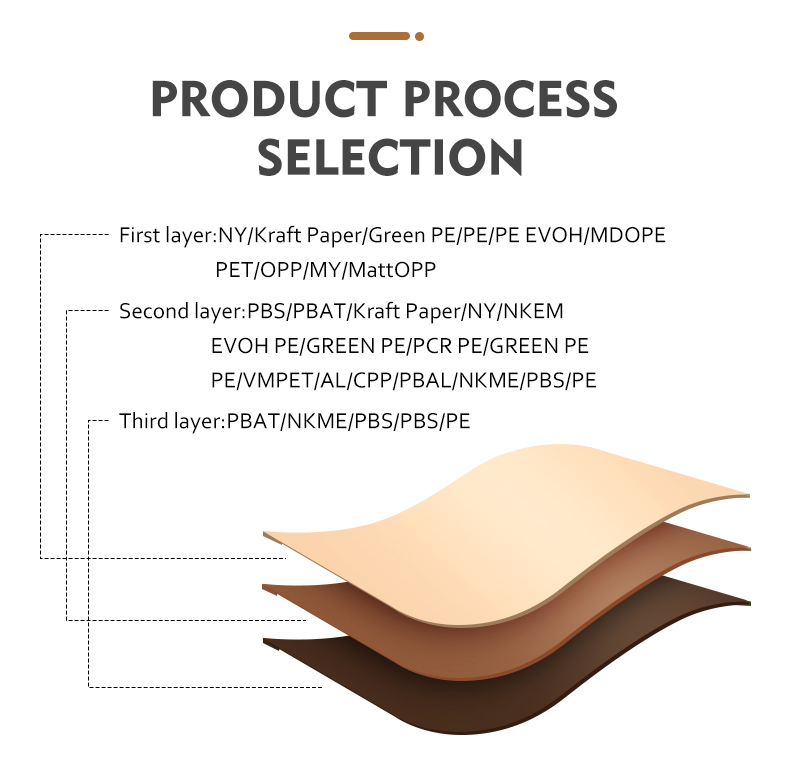

The triple-layered film structure employed in coffee bean bags is a sophisticated design that combines different materials to create a synergistic protective barrier, ensuring the optimal preservation of coffee beans. Let's delve into the detailed composition and functions of each layer:

Inner Layer (PE - Polyethylene):

Function: The innermost layer of the film is in direct contact with the coffee beans. Polyethylene (PE) is chosen for its non-toxic nature, chemical stability, and remarkable resistance to most acids and bases. Importantly, PE does not react with the components of the coffee, ensuring that the beans remain free from any undesirable interactions during storage.

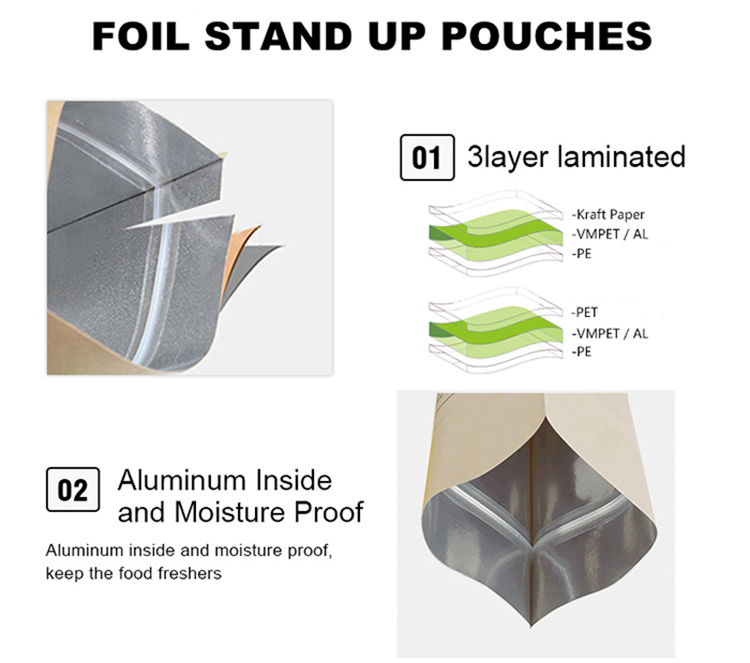

Middle Layer (AL - Aluminum):

Function: Serving as a protective barrier, the middle layer is crafted from high-purity aluminum (AL). This layer offers a unique combination of lightweight strength, light reflection properties, and airtight moisture protection. The lightweight strength provides durability without adding unnecessary weight, while the reflective nature of aluminum helps shield the beans from excess light, a known factor that can contribute to flavor degradation. The airtight quality of aluminum safeguards against moisture, preserving the freshness of the coffee beans.

Outer Layer (PET - Polyethylene Terephthalate) or Kraft Paper:

Function: The outer layer acts as the final protective shell of the coffee bean bag. It can be crafted from Polyethylene Terephthalate (PET) or environmentally conscious alternatives like Kraft paper.

PET:

Provides non-toxic and odorless protection.

Offers high strength and excellent printability, allowing for vibrant and informative packaging designs.

Kraft Paper:

Serves as a biodegradable alternative, aligning with the preferences of environmentally conscious consumers.

Boasts a natural color, reducing the need for extensive printing and contributing to a more eco-friendly packaging solution.

One-Way Degassing Valve:

Positioned on the front of the bag, the one-way degassing valve comprises a top cap, base, and suction piece. When internal pressure surpasses the valve's threshold, gases escape through the bottom, preventing bag rupture. External pressure cannot penetrate the bag, maintaining an optimal environment inside.

Convenient Zipper and Pull Tab:

Featuring a user-friendly zipper and pull tab at the top, the bag ensures easy opening and resealing. An internal sealing strip enables a secondary closure, promoting prolonged freshness once the bag is opened.

In addition to these features, the industry is witnessing a shift towards eco-friendly alternatives. Some manufacturers are now incorporating biodegradable materials into their coffee bean bags, aligning with the growing environmental consciousness of consumers.

Within the context of aluminum foil coffee bean bags, the selection of aluminum foil is a pivotal aspect in ensuring the preservation of coffee beans at its best. The choice of aluminum foil is not arbitrary; it is a carefully considered decision due to the unique properties that aluminum brings to the packaging:

Thermal Conductivity:

Advantage: Aluminum foil has excellent thermal conductivity. This means it can effectively shield the coffee beans from external temperature fluctuations, ensuring that the beans are not subjected to extremes that could compromise their quality. It acts as a thermal barrier, preventing heat from infiltrating the bag.

Light Reflection:

Advantage: Aluminum, being a reflective material, plays a crucial role in protecting coffee beans from light exposure. Excessive light can lead to the degradation of coffee flavors. Aluminum foil in the bag reflects light away, preserving the beans in a more optimal environment.

Moisture Resistance:

Advantage: Aluminum foil provides a superior barrier against moisture. The impermeable nature of aluminum ensures that external humidity does not penetrate the bag, safeguarding the freshness and flavor of the coffee beans.

Lightweight Strength:

Advantage: While being robust and protective, aluminum foil remains lightweight. This is advantageous for transportation, reducing the overall weight of the packaging without compromising the integrity of the bag. It contributes to more sustainable and cost-effective logistics.

Inert Nature:

Advantage: Aluminum is an inert material, meaning it does not react with the coffee components. This ensures that the original flavors and aromas of the coffee beans remain untainted, providing consumers with an authentic and unaltered coffee experience.

The careful consideration of aluminum foil as a core component of coffee bean bags demonstrates a commitment to quality preservation. Its multifaceted benefits contribute to the overall efficacy of the packaging, assuring consumers that the coffee beans enclosed within the bag are protected against a range of external factors that could compromise their freshness and flavor.