paper packaging bags supplier custom paper bags factory quality paper bags,

Paper packaging bags,

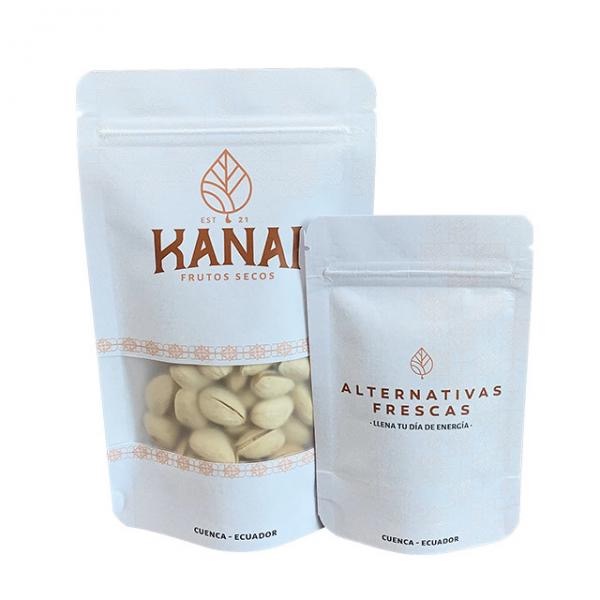

Paper packaging bags, as the name suggests, use paper as packaging materials to make packaging containers to protect the packaging. paper packaging bags are usually used for shopping in supermarkets, shopping malls, clothing stores, shoe stores, gold and silver jewelry stores and other places to facilitate customers to carry purchased items. Many food paper packaging bags are also used in bakeries, cake shops and other snack packaging. We are a professional paper packaging bags supplier and can customize all kinds of paper packaging bags.

paper packaging bags, paper packaging bags supplier, paper packaging bags factory, buy paper packaging bags from paper packaging bags manufacturer, we will give you best paper packaging bags services

| MATERIAL: | Aluminum Foil | INDUSTRY USE: | Tea |

|---|---|---|---|

| USE: | Coffee | MOQ: | 10000 |

| LOGO: | Accept Customized Logo | PRODUCT NAME: | paper packaging bags |

| SIZE&THICKNESS: | Custom Sizes Tissue Packaging Bags | COLOR: | Customized Color |

| PRODUCTION TIME: | 12 Working Days | ||

| HIGH LIGHT: | paper packaging bags supplier custom paper bags factory quality paper bags | ||

Scope of application of paper packaging bags

Supermarkets, shopping malls, clothing, daily chemical products, jewelry industry, food industry, agricultural products, electronics industry, toys, hardware and other industries need paper packaging bags.

According to the material, it can be divided into: a. Pure kraft paper packaging bag b. Kraft paper with aluminum foil (paper-plastic bag) c. White cardboard with aluminum foil

According to the bag type, it can be divided into: a. Square bottom paper packaging bags b. Side organ paper packaging bags c. Eight-side sealing paper packaging bags d. Vertical zipper paper packaging bags e. Bottom organ paper packaging bags

According to the appearance of the bag, it can be divided into: a. flat paper packaging bags b. valve paper packaging bags. c. square bottom paper packaging bags. d. sewing bottom paper packaging bags. e. heat sealing paper packaging bags. f. hot Square bottom paper packaging bags

Applicable type of paper packaging bags: one-time use

Material: Polypropylene, Kraft Paper, Aluminum Foil

Capacity: 100g-2500g

Production method: paper back cover, heat back cover, paste bottom.

Classification of paper packaging bags

Paper bags can be divided into: pure wood pulp paper packaging bags, news newspaper paper packaging bags and paper-plastic composite paper packaging bags according to the material.

Pure wood pulp paper has the advantages of strong water resistance, sun resistance, not easy to deform, and not easy to break when exposed to wind and rain. Paper packaging bags can be divided into: single layer, double layer and three layers according to the number of layers. According to the difficulty of coloring the variety, choose the appropriate number of layers of paper packaging bags. For varieties that are difficult to color, it is advisable to choose double-layer paper packaging bags. At the same time, the color of the paper packaging bags is also required. The surface of the outer bag is gray, green and other colors, and the inside is black; the inner bag is a waxy red bag, and the bottom tube is not sealed. For varieties that are easier to color, you can choose single-layer paper packaging bags, which are gray, green and other colors on the outside and black on the inside. The outer bag of the double-sided paper bag mainly plays a protective role. When the fruit is mature, the outer layer of the paper packaging bags is removed, and the colored translucent paper of the inner layer of the paper bag is conducive to better coloring of the fruit. After removing the bag, if it can be combined with fruit turning and leaf picking, the effect will be better.

Newspaper paper paste packaging bags originated in the 1940s, but because they are easy to break, they cannot play a protective role, which can cause the quality of the fruit to decline. Later, the use was gradually reduced. For the special needs of certain varieties, such as Jinshuai apples, in order to prevent fruit rust, newspaper paper packaging bags or yellow waxed single-layer paper packaging bags can be used.

The paper-plastic composite packaging bag can make up for the defects of a single set of paper packaging bags or a single set of plastic film paper packaging bags. It is both breathable and light-transmitting. The invention of the paper-plastic composite packaging bag is a major change in fruit tree bagging technology. Many fruit farmers are worried that paper-plastic composite packaging bags have not been widely used.

Application of paper packaging bags

The advantage of paper packaging bags is environmental protection. Paper packaging bags is an environmentally friendly packaging bag, among which kraft paper packaging bags and white cardboard packaging bags are the most used and have the widest range. Kraft paper packaging bags are non-toxic, odorless, non-polluting, comply with national environmental protection standards, high strength and high environmental protection, and are one of the most popular environmentally friendly packaging materials. Paper packaging bags are used for shopping in supermarkets, shopping malls, clothing stores, shoe stores, gold and silver jewelry stores and other places to facilitate customers to carry purchased items. Many food paper packaging bags are also used in snack packaging such as bakeries and cake shops. The color of the paper packaging bags is divided into white kraft paper, also called white cardboard and yellow kraft paper. PP coating can be used on the paper to play a waterproof role. The thickness of the bag material can be made into one to six layers according to customer requirements. For heat sealing, paper sealing and pasting

Four types of paper commonly used in food packaging paper bags

People's voice for health and environmental protection is increasing day by day, and green and environmentally friendly paper packaging bags is widely used in people's daily life again. For example, food-grade paper packaging applications, food paper packaging bags are widely used, from small oil-proof paper packaging bags and snack bags in food stalls to large food paper packaging bags , paper pads, takeaway bags, etc., such as McDonald's and KFC. Moreover, it has also changed from the traditional style of single color to the present, with various styles and exquisite printing. So, what kind of paper are the food paper packaging used in the food market customized?

When customizing paper food packaging bags, there are many types of paper to choose from. There are four kinds of paper that are often used: kraft paper, coated paper, white cardboard, and offset paper. Different types of paper have different toughness, smoothness and aesthetics. When customizing paper bags, food packaging bag manufacturers will compare and choose according to the use of paper bags and the characteristics of different papers to meet customer needs. Next, Lianxing Paper will briefly introduce the characteristics of these four kinds of paper commonly used for making paper packaging bags.

1. Kraft paper: It is made of coniferous wood sulfate natural pulp, which has high strength, usually yellowish brown, in addition to light brown, cream or white. The thickness is between 80 grams and 120 grams. Kraft paper has a high tensile force, with single light, double light, stripe, no grain and so on. It is mainly used to make environmentally friendly portable paper bags for supermarkets, food takeaway paper bags, packaging paper bags for chestnuts and other dried fruits, envelope bags, file bags, medical record bags, etc.

2. White cardboard: single-layer or multi-layer combination produced by bleached chemical pulping and fully sizing. White cardboard has a smooth surface and firm texture. At present, imported white cardboard occupies a larger market share in the domestic market. White cardboard is mainly used to make high-end and exquisite handbags, packaging bags, gift boxes, business cards, etc.

3. Coated paper: The main raw materials are coated base paper and paint. Pigments, binders and auxiliary materials are made into coatings, which are coated on the surface of cardboard by special equipment, dried and calendered. The surface is smooth and clean, and the printing performance is good. Labels, cartons, etc.

4. Offset paper: the paper surface is white and smooth, but the whiteness, tightness and smoothness are lower than that of coated paper, suitable for printing monochromatic or multi-color book covers, text, inserts, pictorials, maps, posters, color trademarks And various packaging products, in recent years, it has also been used to make dry fruit packaging bags such as chestnuts with low requirements.

Paper packaigng bags, paper packaging bags sullier, paper packaging bags factory, we produce food paper packaging bags, coffee paper packaging bags, custom paper packaging bags etc, buy quality paper packaging bags from paper packaging bags manufacturer, as a paper packaging bags supplier, we can custom different kinds of paper packaging bags for you, welcome to visit our paper packaging bags factory, we shure we will be your best paper packaging bags supplier china