MST Flat Bottom Coffee Bags, Finish Effect for Flat Bottom Coffee Bags manufacturers Support customization various materials.also Support use various printing techniques to create attractive designs and branding that helps to make Flat Bottom Coffee Bags, Finish Effect for Flat Bottom Coffee Bags stand out on the shelves. help you choose the most suitable Flat Bottom Coffee Bags, Finish Effect for Flat Bottom Coffee Bags for your needs.

Embossed Finish Effect for Flat Bottom Coffee Bags

Embossed finish: An embossed finish gives the bags a raised texture or pattern, which can be used to create a tactile and visually interesting surface. This finish can also help to make the bags more durable and resistant to tearing.

An embossed finish effect for flat bottom coffee bags involves creating a raised or textured pattern on the surface of the bag material to add visual interest and tactile sensation. This effect can be achieved through a variety of techniques, such as heat embossing, cold embossing, or using textured rollers during the printing process.

Embossing adds depth and dimension to the design of the coffee bag, making it stand out on the shelf and appealing to the customer's sense of touch. It can also help to create a more premium look and feel for the packaging, which is important for coffee brands that want to communicate quality and luxury.

In addition to the visual and tactile benefits, embossing can also improve the functionality of flat bottom coffee bags. The raised pattern on the bag surface can help to improve grip, making it easier for customers to hold onto the bag while pouring or opening it. It can also add structural stability to the bag, making it more resistant to crushing or deformation during transportation and handling.

|  |

3D touch Finish Effect for Flat Bottom Coffee Bags

3D touch finish effect is a technique used in printing to create a textured, tactile feel on the surface of a printed material. This effect is achieved by using special inks and printing techniques that create a raised, embossed texture on the printed surface.

In the case of flat bottom coffee bags, the 3D touch finish effect can be used to create a textured, tactile feel on the surface of the bag that mimics the texture of coffee beans or other related imagery. This can add a premium, high-end feel to the bag and make it stand out on store shelves.

To achieve the 3D touch finish effect, a special printing process is used that involves applying a thick layer of ink to the surface of the bag. This ink is then heated and cured to create a raised, textured surface. The end result is a flat bottom coffee bag with a tactile, textured feel that adds depth and dimension to the design.

Overall, the 3D touch finish effect can be a great option for flat bottom coffee bags that are looking to stand out on store shelves and create a premium, high-end feel.

Flat Bottom Coffee Bags with hot stamping Finish Effect

Hot stamping technology refers to the transfer of hot stamping foil to the surface of the printing material by means of heating and pressure using a special metal hot stamping plate.

The advantages of hot stamping technology mainly include the following points.

Good quality, high precision, clear and sharp edge of hot stamping image.

The surface gloss is high, and the hot stamping pattern is bright and smooth.

There is a wide selection of hot stamping foils, such as hot stamping foils in different colors, hot stamping foils with different gloss effects, and hot stamping foils for different substrates.

Another outstanding advantage of the hot stamping process is that it can be used for three-dimensional hot stamping. The three-dimensional hot stamping plate is made by computer numerical control engraving (CNC), so that the graphics and texts processed by hot stamping have obvious three-dimensional layers, forming a relief effect on the surface of the printed matter, and producing a strong visual impact effect. Three-dimensional hot stamping can give the packaging a unique touch.

It is precisely because the hot stamping process has the above-mentioned many advantages that it has been favored by the majority of users and consumers and is widely used.

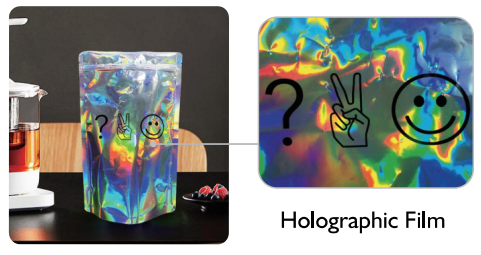

Holographic film Finish Effect for Flat Bottom Coffee Bags

The holographic film finish effect is achieved by using a special type of film that reflects light in a unique way. The film has a multilayered structure that diffracts and reflects light at different angles, creating a three-dimensional holographic effect. The result is a dazzling array of colors and patterns that seem to change as the angle of view changes.

Holographic film improves packaging security and appearance. It has good processing adaptability and other characteristics in packaging, and is very suitable for mechanized production. It has excellent light-shielding, moisture-proof, gas-barrier and taste-preserving properties, and plays an almost absolute barrier protection effect on the light, gas, humidity and taste of coffee beans, thus greatly improving the shelf life of coffee beans. Due to the additional laser holographic processing technology of laser holographic aluminum foil, counterfeiters cannot easily obtain or copy the same material, so it can improve the anti-counterfeiting performance of coffee.

| Foil stamping Finish Effect for Flat Bottom Coffee Bags When it comes to flat bottom coffee bags, foil stamping can be used to create a range of effects, including metallic accents, holographic designs, and custom patterns. The foil is typically applied to specific areas of the bag, such as logos, text, or graphic elements, to create a contrast with the rest of the bag's design. Hot stamping process has many advantages: Hot stamping process Its whole surface hot stamping products have no ink residue.The color pattern of the hot stamping process is completed in one hot stamping process, which can reduce loss.The process of bronzing process is relatively simple, the production and process are relatively smooth, and the quality assurance is relatively large.The bronzing process has no unpleasant smell and no pollution to the air. Foil stamping can add significant value to flat bottom coffee bags, making them more eye-catching and appealing to customers. It can also help to communicate a brand's values and personality, as the use of metallic or colored foils can evoke different emotions and associations. In addition to its decorative benefits, foil stamping can also improve the functional properties of flat bottom coffee bags. The foil layer can provide a barrier to moisture and light, helping to preserve the quality and freshness of the coffee inside. |

Coffee bags supplier

MST PACK is a honest coffee bags supplier in China. We provide the highest quality Flat Bottom Coffee Bags and other product packaging solutions for coffee industry. We pay special attention to manufacture Flat Bottom Coffee Bags, Finish Effect for Flat Bottom Coffee Bags, flat bottom brown craft paper coffee bags. Here is our factory tour, click coffee bags factory tour and know more about our coffee bag production process. All our product have quality control, we firmly pursue strict quality management, pursuing perfect quality. Our customers are all over the world, and there are offices in Europe and Australia. Feel free to contact us get Flat Bottom Coffee Bags quote.